Water electrolysers are well known both at industrial scale and in laboratory applications. Alkaline electrolysers can produce large quantities of gas at relatively high pressure. These devices only become economically attractive at very large scale and are most usually grid –connected although can be powered using significant amounts of photo-voltaics. Laboratory electrolysers used to produce small amounts of highly pure hydrogen are usually based on proton exchange membrane technology (PEM) but unit costs are high as they are tailored for high precision applications. However, a number of PV powered lab based PEM electrolysers have been demonstrated using renewable energy sources to power the unit.

Recent innovative advances by companies such as ITM Power in PEM electrolyser technology signal a route to low cost, economic hydrogen production at the intermediate scale.

Regenerative fuel cell technology under development in companies such as Infinity Fuels is very attractive for PV driven applications. The single device can either be operated in one direction like a PEM electrolyser to generate hydrogen and oxygen from water using electricity supplied to the unit. In reverse, if hydrogen and oxygen are fed into the unit, it functions as a PEM fuel cell producing electricity and water as a by-product. Therefore during intense sunlight and low electricity demand periods the unit can be used to generate gas from the excess power generated from photovoltaics. During periods of high electricity demand and periods of darkness electricity can be generated by using the system in reverse. Thus saving on system parts and integration complexity and leading to much lower costs.

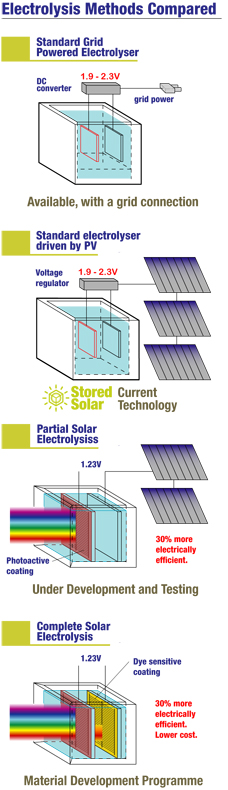

The current range of electolysers all use high currents with voltages around 2 volts to enable electrolysis to be undertaken. Just as the costs for the electrolyser units decrease, a reduction in the cost of power used to drive the units would also improve the economics. One such way to achieve this is to use solar electrolysis, in which the voltage required to enable the water splitting is reduced and can potentially be dispensed with.

© Copyright 2008 Stored Solar Limited | Privacy Policy | Site Map | Terms and Conditions